Forging Operations

- 1x 1,600 Ton Mechanical Forging Press

- 2x 2,000 Ton Mechanical Forging Press

- 5x 2,500 Ton Mechanical Forging Press

- 1x 4,000 Ton Mechanical Forging Press

Each mechanical press has a dedicated computer-controlled induction heating system and trim press

Rex Forge also has a variety of Drop Hammers capable of producing less technically demanding forgings

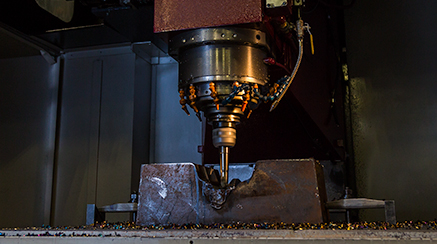

Tool and Die Shop

- Doosan 3-axis CNC Vertical Machining Center

- OKK VM7 3-axis CNC Vertical Machining Center

- 7x Maxicut Electrical Discharge Sinker Machine